Plastic Injection Mold Tooling

Mold Building

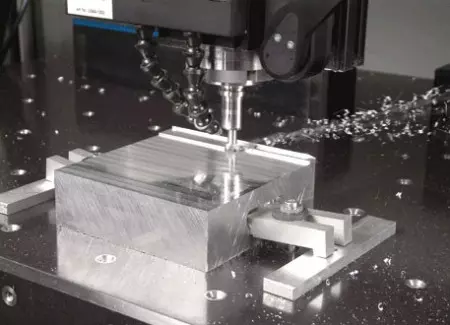

Precision Mold Building for Injection Molded Plastics

TERA has been building the most complex, precision mold since 1998. TERA's tooling operation is an innovative precision tool and mold making facility that is fully integrated with TERA's in-house design and production services. Speed and accuracy are driven by machining center robotics, the latest in design technologies and highly skilled toolmakers. Product design changes are communicated electronically, in real time to the machine programmers who are shaping the steel. TERA's machines are utilized for the maximum in unattended hours and coverage is provided on nights and weekends.

Mold Build Specialists

Production Multi-cavity Molds

Quick Change Molds

Multiple Slide Action Molds

Insert Molds

Precision CNC Machining

Custom Wire and Ram CNC EDM

Close Tolerance Spare Tooling

Design and Development

Production Quality Prototypes

CNC Rapid Prototypes

Hot Runner System

Shuttle and Insert molds

TERA's design and tooling specialists utilize mold simulation software to optimize the product design and manufacturing process. And this process reduces the time needed to condition the mold and speeds the product to market.

Contact us today to learn more about the quality and value TERA injects into every mold build or to submit engineering files for quotation.