SERVICE

ODM & OEM

TERA PLASTIC is a ODM (Original Design Manufacturer) and OEM (Original Equipment Manufacturer) company. With more than 28 years of intensive experience in plastic industry, TERA Plastic provide our customers with great service and competitive quotation.

Our services include:

1. Product design

2. Prototyping

3. Injection mold tooling

4. Injection molding

5. Secondary service

6. Vacuum forming

Our service is customizable, below is standard process:

The Custom Injection Molds, Plastic Injection Molding Manufacturing and Services Flow as below:

- Receive the 2D/3D data.

- Do feasibility study.

- Review the mold standard and requirement, submit it to the designer.

- Have the verdict meeting to decide the layout

- Start designing.

- Print out the preliminary drawing and have the review meeting.

- Revised the drawing according to the comments on review meeting.

- Submit the preliminary drawing to customer.

- Perfect the drawing as per the feedbacks.

- Submit the drawing to customer again if needed.

- The customer approve to order & cut steel.

- Order insert material, mold base, hot runner system (if needed).

- Issue out the mold drawing and detail drawing.

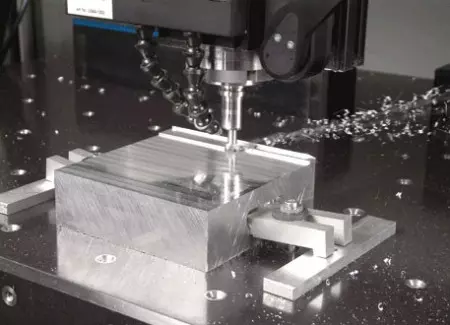

- Start manufacturing , QC will check the component after every procedure.

- Fit the mold.

- Polishing and assembly.

- Mold trial T1.

- Deliver T1 samples to customer.

- Measuring the samples.

- T1 mold review meeting.

- Receive the feedbacks of T1 samples.

- Modify the mold.

- T2.

- Send out the T2 samples for approval.

- T3.

- Approve OK.

- Arrange shipping.

Customers' satisfication is our first priority, and we always get positive feedback from customers.

Plastic Product Mold Design

TERA Design Team help ensure your product can be manufactured. Our experienced teams of engineers are experts in mold design and use the latest engineering tools and software to help you construct a quality plastic part. This allows our tooling engineers to create the best possible and cost effective mold for your project requirements. We can review your mold design, 3D files, or part drawings and provide feedback on possible quality issues or areas in need of improvement.

Plastic Prototyping

Prototypes are important in the development process of plastic injection molded components, saving time and money by helping detect design flaws and other issues in the design phase. With over 27 years of experience in providing injection molding prototypes, TERA Plastics will work with you to develop injection molding prototypes that will work successfully for your project.