Plastic Injection Molding

TERA has more than 27 years experience in plastic injection industry and satisfy customers with best service. Whether your product is as small as a micro gear in the camera or as big as a bezel of TV screen, we have more than 90 injection machines ranging from 80 to 800 tons to meet different product requirements from different customers.

Production for Custom Injection Molded Plastics

TERA Molded Plastics specializes in Scientific Processing and lean manufacturing of complex injection molded plastics in the electronics, medical, automotive and consumer industries.

TERA's production facility operates 24 hours a day and 7 days a week on 90 molding presses ranging from 80 to 800 ton.

Scientific Processing of Engineering Grade Resins

TERA's service extends beyond a complex geometry molded part and intricate product. You receive scientific processing for all grades of engineering resins that require:

- Design for process tooling techniques focused on material properties

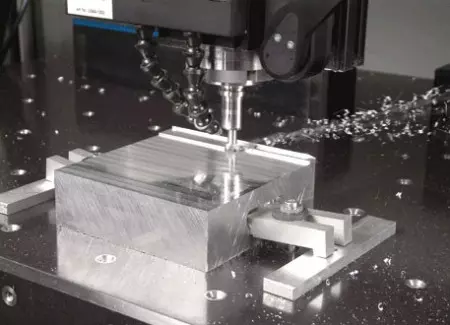

- Extremely close tolerance tooling and inspection criteria

- Research & development, technical support, and supplier integration

- Precision Cooling/Heating temperature control systems

Diverse industry experience in high performance resin and processing knowledge reduces development time and improve the approval process for critical and complex molded plastics.

Injection Molding Press Specs for Tech Molded Plastics

TERA Molded Plastics utilizes more than 90 injection molding presses ranging in size from 80 Ton to 800 tons. TERA continuously invests in technology and training with an average age of production presses less than five years.

TERA's press capabilities and various barrel sizes make it possible for us to assist you with micro molding projects and larger part, high volume molding, across industry segments in consumer, electronics, medical and automotive.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)